What do we produce?

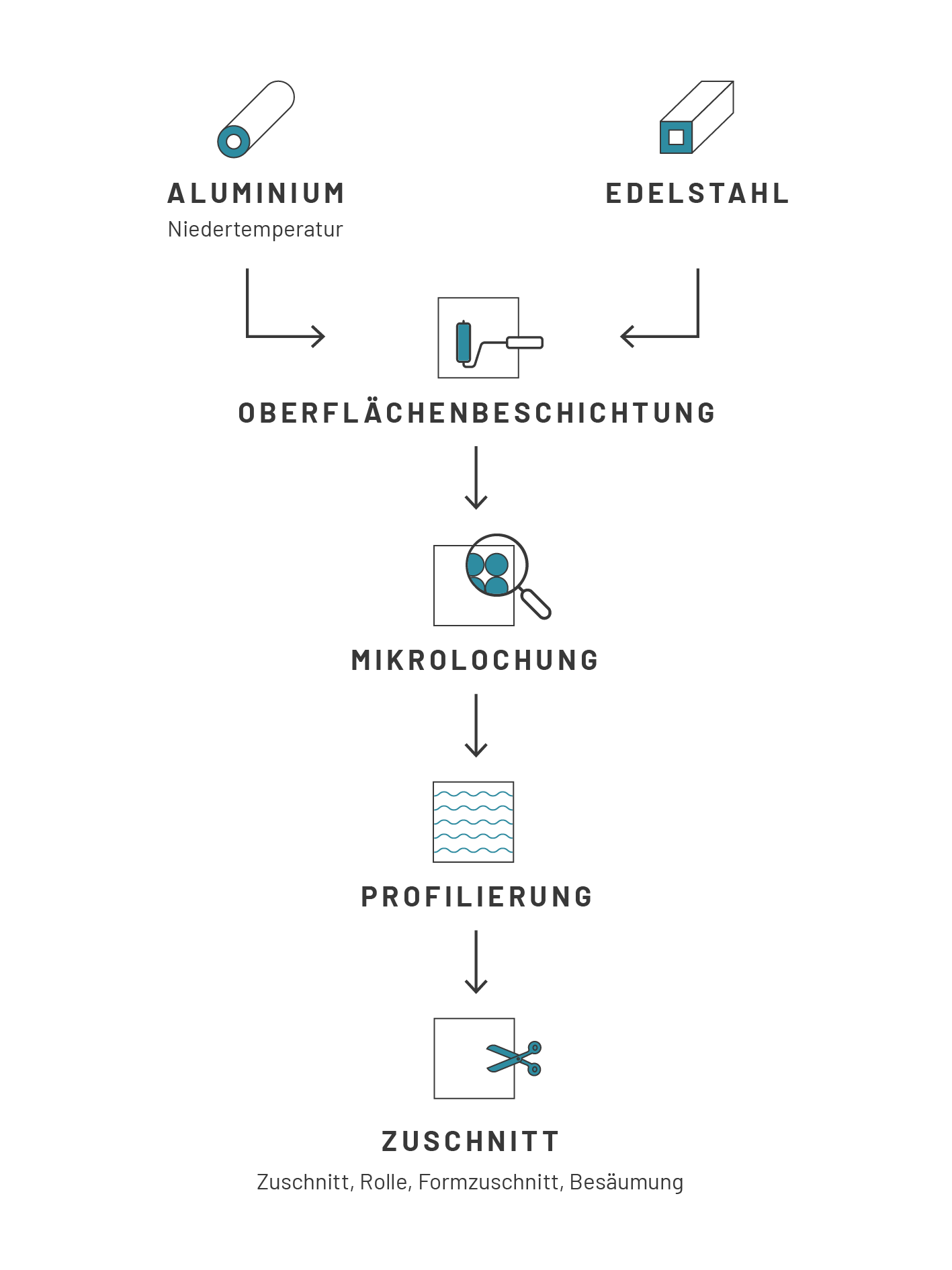

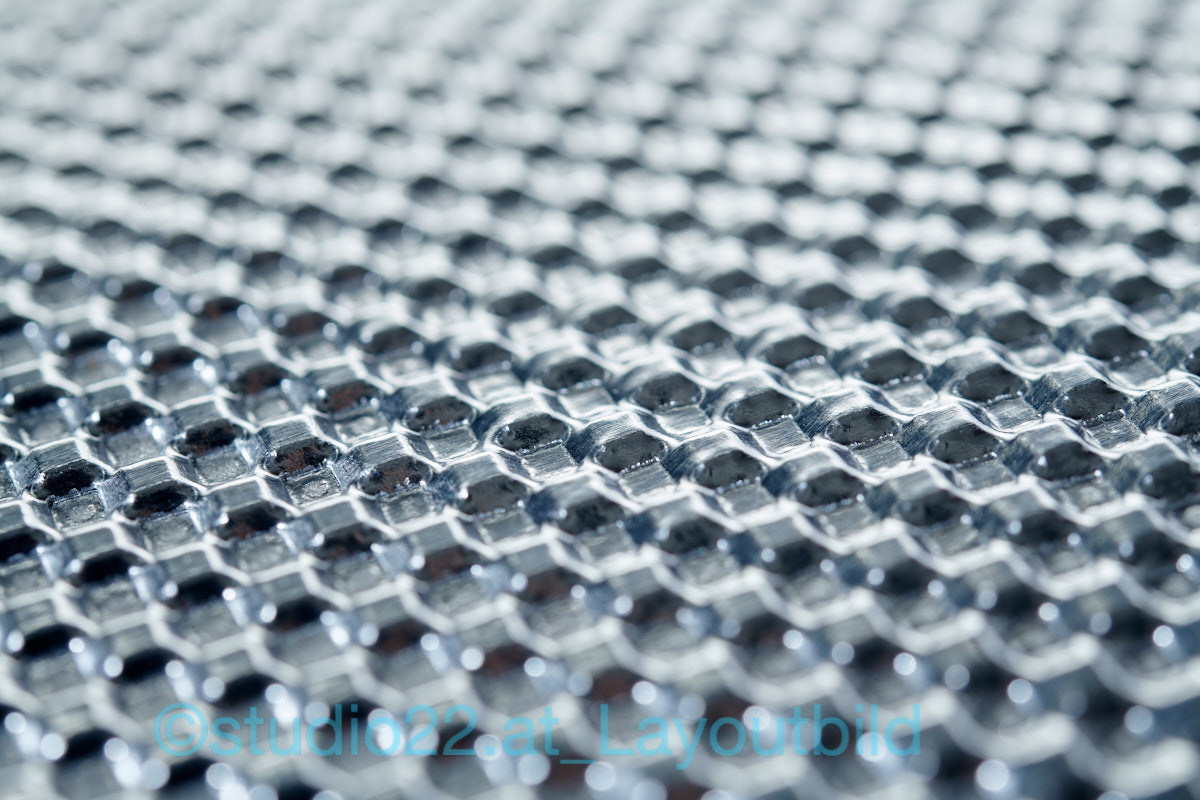

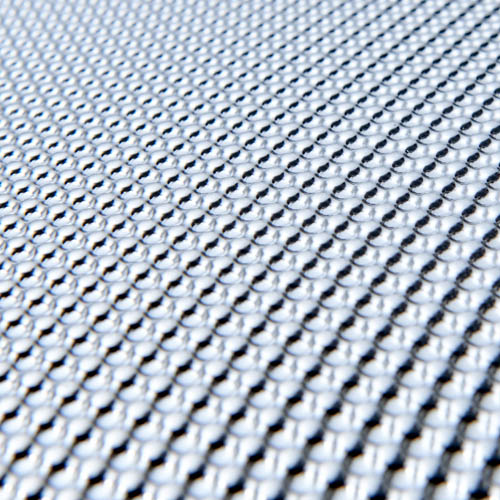

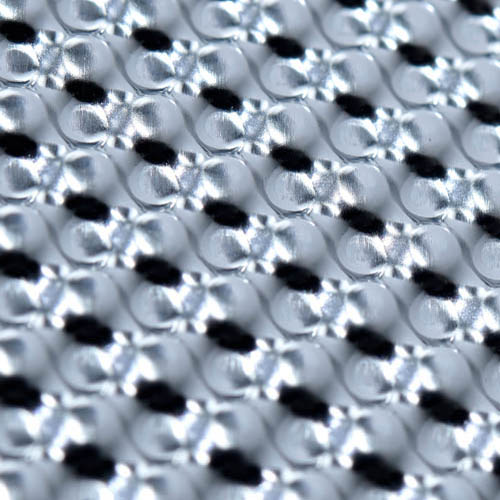

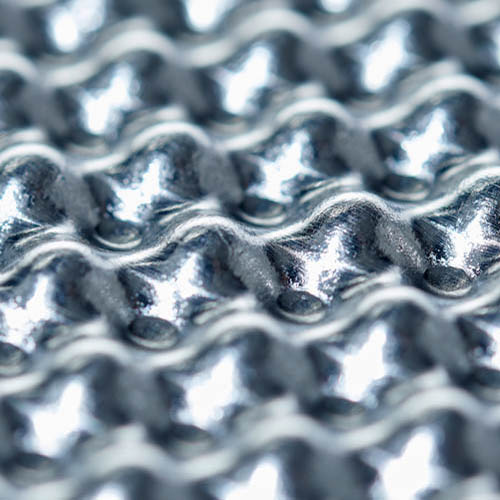

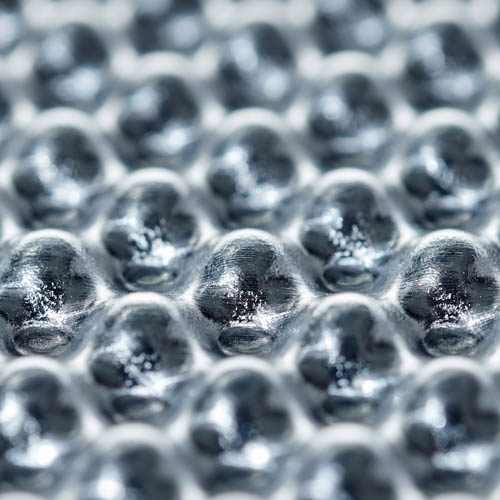

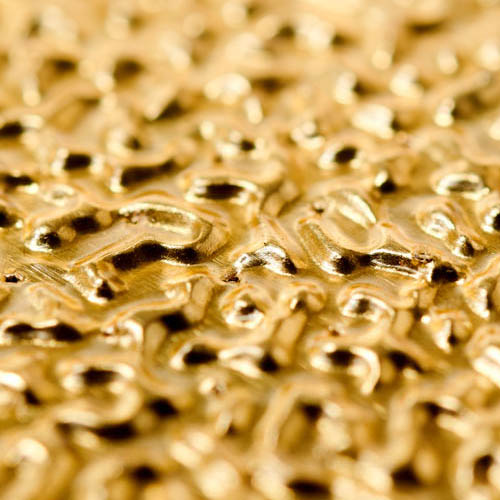

This is what our name Kalotte reveals: Our production facilities produce kalotte-finished profiled sheets, integral insulation from stainless steel, aluminum and steel foils. These inner and outer liners are crucial elements within exhaust systems and are indispensable for them.

Our product

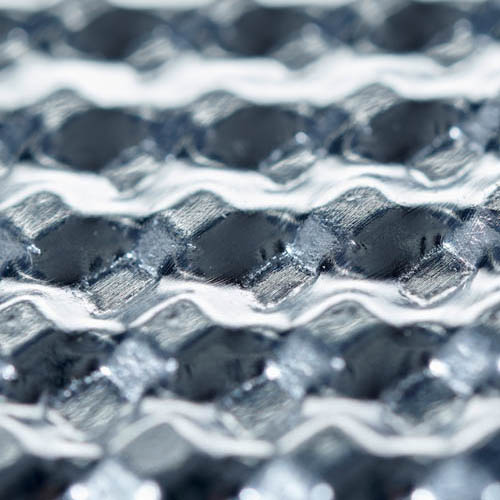

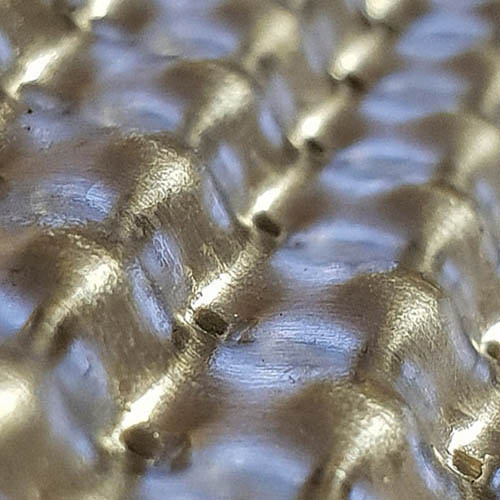

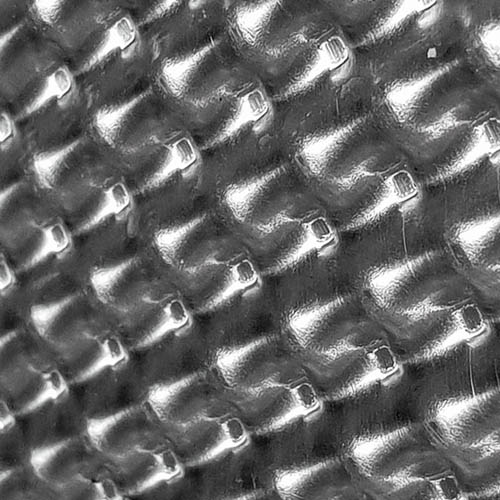

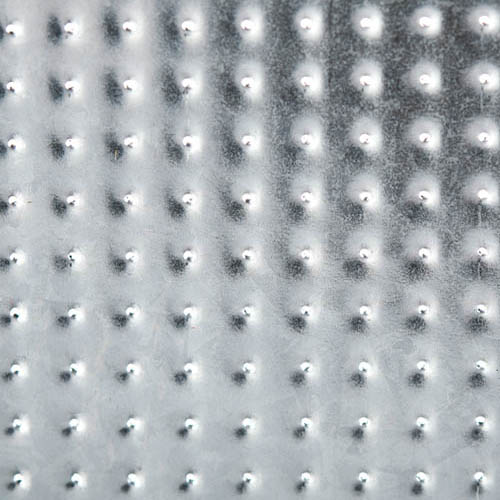

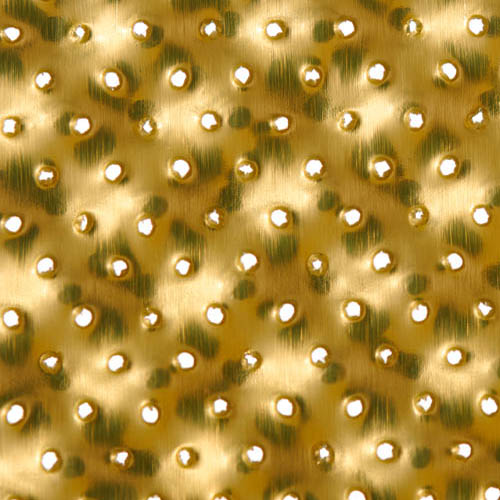

Parts of the exhaust system: Micro-perforated, calotte-finished metal foils and profiled sheets as inner and outer liners in top quality.

Our materials: steel, stainless steel, aluminum and hybrid applications. Inner and outer liners of exhaust systems play an essential role in ensuring temperature resistance. Their functions range from insulation and protection against overheating to heat dissipation. Thus they contribute significantly to the efficiency and longevity of the overall system. The careful selection and use of these components is of great importance for the functionality and performance of automotive exhaust systems.

Kalotte - we bring the future to energy processes

Areas of application

01

E-vehicles

- Overheating protection of batteries reduces risk of fire

- EMC – electromagnetic shieldings improves electromagnetic compatibility

02

Internal combustion engines

- Integral insulations

- Heat concentration in emission aftertreatment systems

- High-temperature insulations

- Thermal and acoustic insulations

- Protection of vehicle body from heat of exhaust system

03

E-Fuels

- CO² reduction through additional parts for exhaust systems

- Optimized products to reduce weight of exhaust systems

- Accelerated deployment of emission aftertreatment

- Fire protection on vehicles

04

future technologies

- Heat management: dissipating waste heat in energy conversion processes

- Energy savings in ventilation technology

- Optimizing electricity storage in residential buildings

- Securing electricity storage systems for SME sized electricity producers

Overview

Our material

Parts in

material thicknesses from 0.05 – 1 mm

- Edelstahl (Stainless steel)

1.4828, 1.4571, 1.4541, 1.4510, 1.4301, 1.4016, … - Heißsiegelfolie / Aluminium Verbundfolie (heat-seal film / aluminum composite film)

Alu 99.5 – PE/PP - Edelstahlheißsiegelfolie / Edelstahl Verbundfolie (Stainless steel heat-seal film / stainless steel composite film)

1.4828, 1.4571, 1.4541, 1.4510, 1.4301, 1.4016, … - Aluminium / Aluminium-Legierungen (aluminum / aluminum alloys)

Al 99.5, AlMg3, … - Aluminierter Stahl (aluminized steel)

DX51-53-56X - weitere Materialien (other materials)

auf Anfrage (on request)

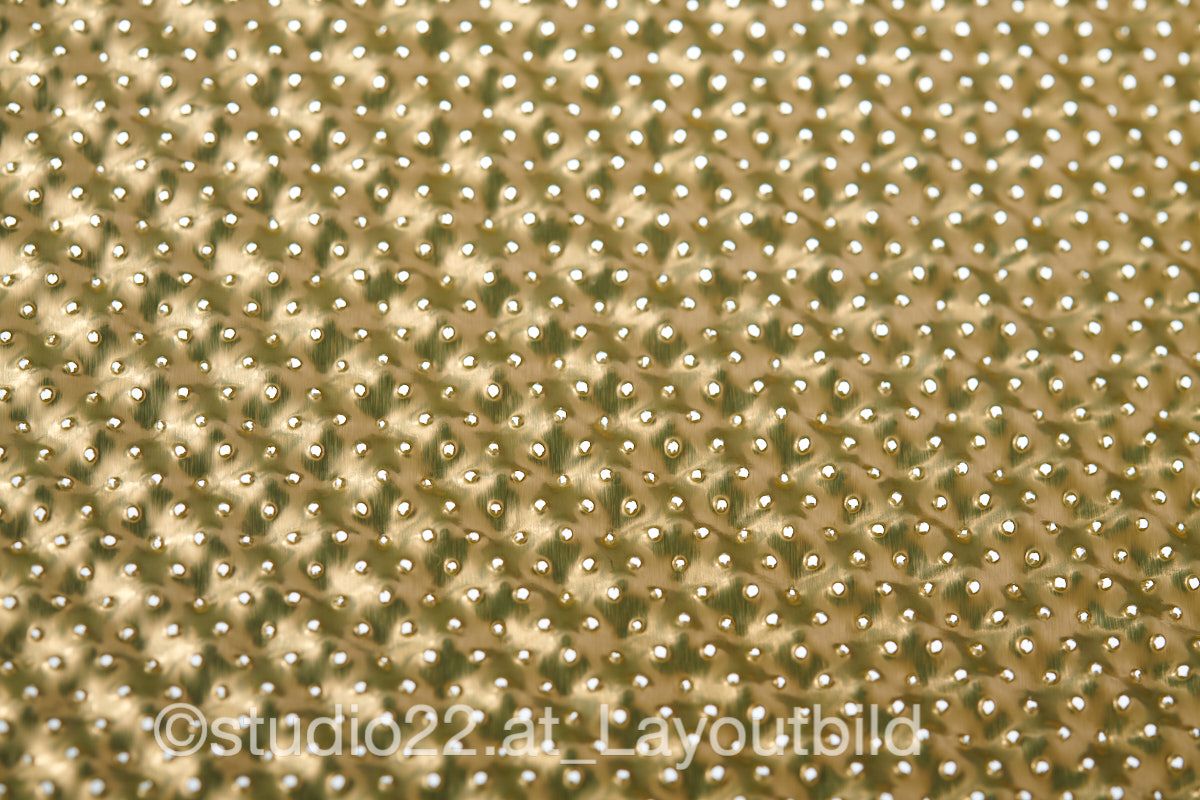

Heat protection thanks to aluminum composite film

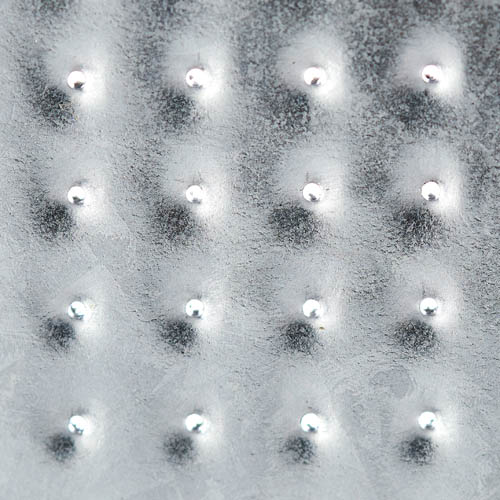

Hot-seal aluminum foil HSK - MSK - PE/PP

Available from Kalotte AG: hot-seal composite foil made of aluminum.

What does “hot-seal” mean in this context? In this process, the thermoplastic coating layer melts and forms an adhesive joint between the substrate and the carrier film. In thermal transfer ribbons, the adhesive strength of the adhesive joint between the substrate and the transfer layer is greater than the adhesive strength between the transfer layer and the carrier film after heat sealing. This means that the carrier film can be mechanically peeled off from the transfer layer immediately after bonding.

Sound-absorbing heat shield

The benefit? This creates a sound-absorbing heat shield together with the carrier plate, i.e. an acoustically and thermally effective insulation layer. On the side facing the sound source, there is a protective film with micro-perforations.

Nutzen

- Drawing behavior through calotte formation improved by up to 45%

- Increase in elongation at break

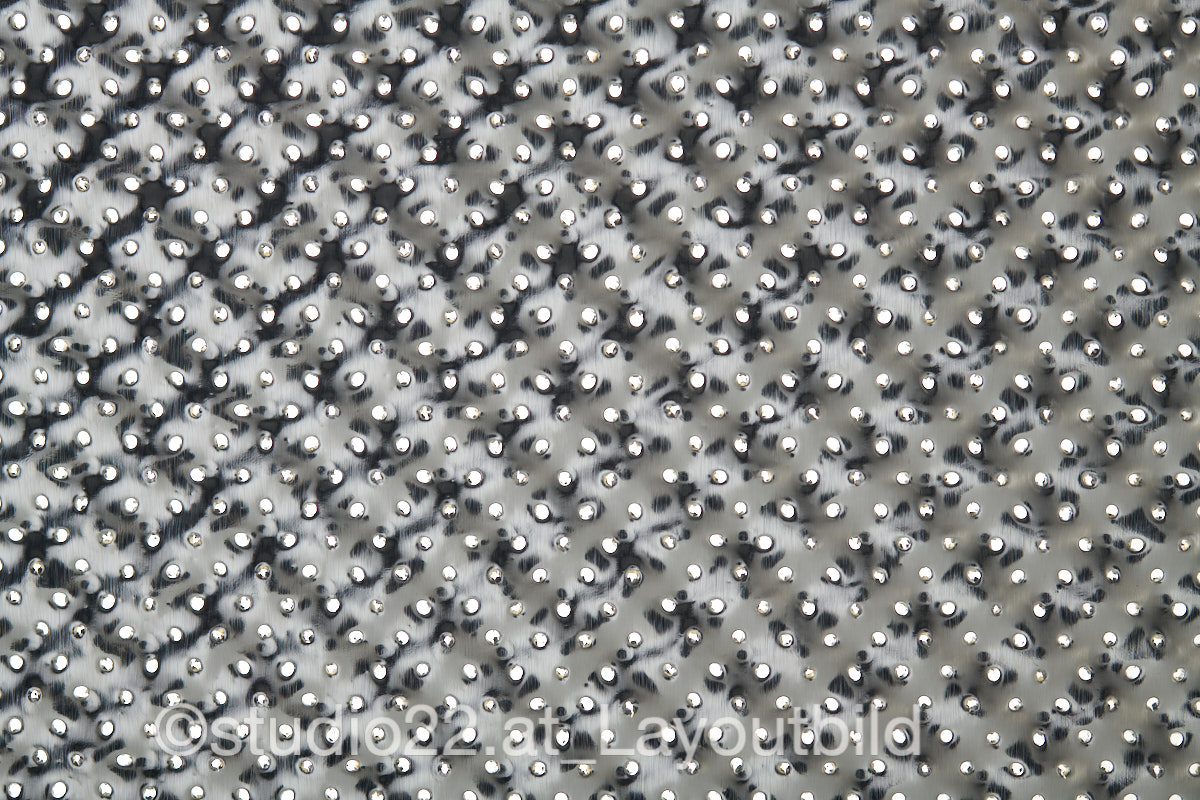

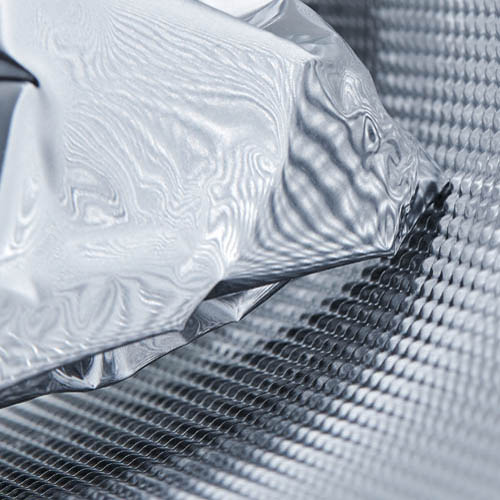

Heat and sound absorption thanks to stainless steel

Hot-seal foil stainless steel

One of the top products of Kalotte AG: hot-seal composite foil made of stainless steel.

What does “hot-seal” mean in this context? In this process, the thermoplastic coating layer melts and forms an adhesive joint between the substrate and the carrier film. In thermal transfer ribbons, the adhesive strength of the adhesive joint between the substrate and the transfer layer is greater after heat sealing than the adhesive strength between the transfer layer and the carrier film. This allows the carrier film to be mechanically peeled off the transfer layer immediately after bonding.

Sound absorbing heat protection

The benefit? This creates a sound-absorbing heat shield together with the carrier plate, i.e. an acoustically and thermally effective insulation layer. On the side facing the sound source, there is a protective foil with micro-perforations.

Nutzen

- easy assembly

- durable, elegant appearance

Heißsiegelfolie Aluminium und Heißsiegelfolie Edelstahl

Anwendung im Vergleich

| Heißsiegelfolie Aluminium | Heißsiegelfolie Edelstahl | |

|---|---|---|

| Temperaturableitung und Isolation | im mittleren Temperaturbereich (punktuell bis 500 °C) | im hohen Temperaturbereich (punktuell bis 1400 °C) |

| für Teile, die vor Elementen geschützt werden, aber schalltechnisch aktiv bleiben müssen | ● | ● |

| Verbrennungsmotoren | ||

| Motorraum | ● | ● |

| Abgasstrang: partieller Schutz für umliegende Teile | ● | ● |

| Unterbodenverkleidung | ● | ● |

| Luftführungen | ● | ● |

| E-Mobilität | ||

| Schutz und Einhausung des Energieträgers: Batterie, Brennstoffzelle, Stromaggregat | ● | ● |

| elektr. Abschirmung | ● | ● |

| Weißwarenindustrie | ||

| Kühlschrank | ● | ● |

| Herd | ● | ● |

| Dampfgarer etc. | ● | ● |

Why stainless steel?

If an elegant design with a durable appearance is required, then stainless steel should be chosen.

Stainless steel heat-sealing film from Kalotte is used for high demands: If aluminum turns white in combination with water over time, stainless steel remains visually the same. Its thermal conductivity is also similar to that of aluminum. However, the tear resistance of stainless steel is many times higher.

All-rounder

Aluminium

Aluminium is a silvery-white light metal. And it is the third most abundant element in the earth’s crust, and the most abundant metal.

What is understood by aluminium in materials technology?

These are all materials based on the element aluminium. They have only one-third the density of steel. In addition, aluminium has a large expansion with good corrosion resistance.

Nutzen

- significantly lighter than steel

- therefore relevant in vehicle construction

- easy to process

- impact resistant

- self-protecting against corrosion:

- upper layer oxidizes

- material does not continue to “rust”

- can be recycled well:

- completely reusable without loss of quality

- only 5% of the energy required for new production – secondary aluminum.

- ignores temperature changes

- vapor impermeable

- UV resistant

- hygienic light metal

- electrical conductivity and magnetic neutrality

Anwendung

- classic heat conduction

- EMC – electromagnetic shielding

- protection of components (intermediate plate)

- between the body and exhaust system, etc.

The alternative

Aluminized steel

(Hot-dip) aluminized sheet steel has the strength of steel with the look of aluminum. It also has excellent resistance to corrosion and heat. Hot-dip aluminizing is a process for applying active corrosion protection to normal steel using conventional means on an industrial scale.

Nutzen

- high-strength sheet metal

- roughly equivalent to steel

- excellent drawing behavior

- affordable alternative to stainless steel

Anwendung

- Exhaust systems

- Hot air ducts

- Domestic appliance industry

Our new addition

HypeGlue® - Stronger than ever

Our new product HypeGlue® fits seamlessly into the line of our top products: HypeGlue® is a hot-seal foil based on aluminum that has excellent adhesion properties to a wide variety of substrates. Your benefit? With HypeGlue®, electromagnetic and heat shielding as well as acoustic damping can be implemented easily.

Ihre Vorteile

HypeGlue® offers numerous advantages over conventional aluminum adhesive films:

- Homogeneous application of the adhesive foil

- Can be activated on a wide variety of substrates as required. Whether selective or full-surface, top adhesion properties are guaranteed.

- The liability of HypeGlue® has been specially developed for fiber composites and non-pretreated products.

- HypeGlue complies with EU standard 94/62/EC.

- Optimal reactivity of the adhesive:

- Can be individually adjusted to the process in a fraction of a second

- Significant increase in tensile strength (deep draw) of our HypeGlue products

- Elongation at break improved by up to 20 %. By comparison, other products achieve 9 – 11 %.

- Your advantage: The susceptibility to cracking is significantly reduced.

- EMC shielding:

- For the first time, a component can be built to be EMC-compliant with the greatest of ease.

- Direct processing of technical residues from the component to be protected

- without cleaning or pre-treatment

- Release agents and light lubricating films are no longer disruptive factors.

Interested? We would be happy to tell you more about our new top product.

HypeGlue – Facts

- homogeneous adhesive metal foil for top adhesion properties

- suitable for fiber composites and non-pretreated products

- EU standard 94/62/EC

- optimal adhesive reactivity:

- can be individually adjusted to the process in a fraction of a second

- Elongation at break of up to + 20 %

- Simple EMC shielding

- Processing without prior cleaning or pre-treatment

Our raw materials

Aluminum

We use aluminum in the low temperature range, which ranges from approx. -50 to 500 °C. Aluminum foil is softer and thinner than stainless steel foil. Available as aluminum heat-sealing foil, among other things, it serves as heat protection, electrical shielding and protection against the elements.

Stainless steel

Stainless steel is used in the high temperature range from -200 to 1400 °C. We process this product into stainless steel heat-sealing foil, which is used as heat protection, protection against the elements, to achieve and maintain the operating temperature and for hybrid applications.